The concept of high pressure airless spraying

High pressure airless spraying, also known as airless spraying, refers to a spraying method that uses a high-pressure plunger pump to directly pressurize the paint to form a high pressure paint, and sprays out of the muzzle to form an atomized air stream that acts on the surface of objects (walls or wooden surfaces).

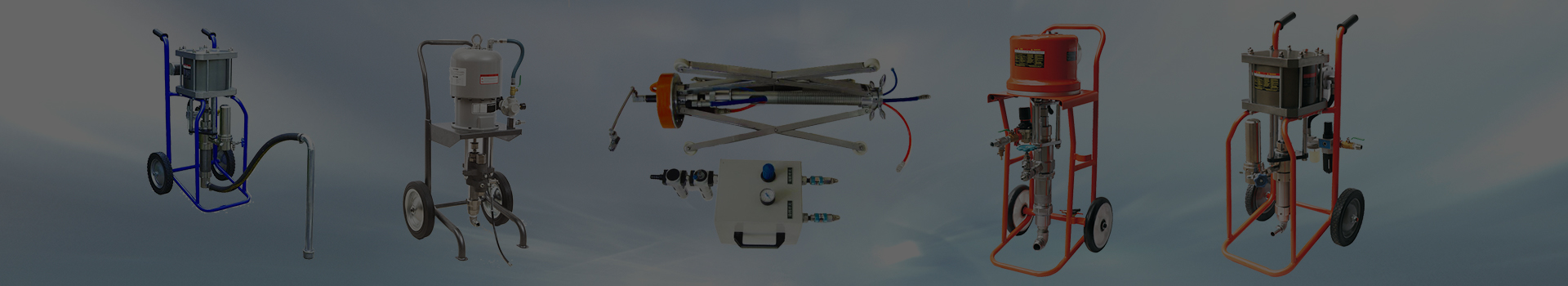

Compared with air spraying, the paint surface is uniform without particle feeling. The paint is dry and clean due to isolation from air. Airless spraying can be used for the construction of high viscosity paint, with clear edges, and even for some spraying projects with boundary requirements. According to the type of machinery, it can also be divided into pneumatic airless spraying machine, electric airless spraying machine, internal combustion airless spraying machine, etc.

Airless spraying can be divided into hot spraying type, cold spraying type, electrostatic spraying type, air assisted type, etc. The development of airless spraying technology and equipment is closely linked.

(1) In the initial stage of airless spraying, gear pump was used to pressurize the coating, but the pressure was not high, and the atomization effect of the coating was poor at room temperature. In order to remedy this defect, the coating is heated in advance and then sprayed under pressure. This method is called thermal spraying airless spraying. Due to the large size of the equipment, its use is limited and it is not widely used.

(2) Later, the plunger pump was used to pressurize the paint. The paint pressure was high, the atomization effect was good, and the paint did not need to be heated. The operation was relatively simple. This method is called cold spraying airless spraying. With high spraying efficiency, less paint spray and thicker film, it is most suitable for large area spraying of large workpieces, so it is widely used. On this basis, pre heating the coating to spray high viscosity coating and high solid coating can improve the atomization effect, improve the decoration, and obtain a thicker film.

(3) Electrostatic airless spraying is the combination of airless spraying and electrostatic spraying, which gives full play to their characteristics and advantages and improves the painting efficiency.

(4) Two component airless spraying is a new method developed to adapt to the spraying of two-component coatings.

(5) Air assisted airless spraying absorbs the advantages of air spraying to improve airless spraying. The spraying pressure is low and only needs about 1/3 of the pressure of ordinary airless spraying.

Post time: Dec-02-2022